Greenland Machinery and the Future of Electric Industrial Vehicles

Raymond Wang, CEO of Greenland Technologies, joins the podcast and explores our partnership to bring autonomy to their industrial vehicle fleet.

RaaS is growing rapidly. Discover roadblocks to adoption and the ways this paradigm makes it easier to tap into new technologies and get work done.

By Melanie Stone

The idea of renting as opposed to purchasing vehicles is growing quickly and has started to gain traction in material handling businesses — this idea is known as Robotics as a Service (RaaS) and it represents a new paradigm in the industry. In fact, ABI Research predicts that there will be 1.3 million RaaS installations by 2026, generating over 34 billion in revenue.

Let’s look into what Robotics as a Service really is, the challenges to adoption, and the ways this shifting paradigm will make it easier to tap into new technologies and get work done.

What Is Robotics as a Service?

First, anything that’s “as a service” means that the business model is moving from ownership, where you buy an asset outright, to a license, lease, or rental model with a subscription service. When you buy equipment or vehicles, you become responsible for maintaining and upgrading the asset over time. Conversely, when you rent, you change the pattern of how you use the equipment and your relationship with the seller or service provider. Instead, the service supplier will offer everything from maintenance to updates and upgrades.

Robotics as a Service, therefore, provides a new avenue to bring industrial self-driving vehicles to new customers.

For Cyngn, Robotics as a Service represents the easiest way for us to put autonomous vehicle technology into a customer's hands without requiring our customers to staff up a maintenance team or hire engineers to get the most value out of such a cutting edge investment.

Why Is This Shift Happening?

Over the years, we have seen the “as a service” paradigm move from cloud-based software to hardware. Today, RaaS is growing rapidly as organizations are looking for new solutions to cope with change. Whether these changes arise from a shifting business model or an increase in demand that leaves organizations scrambling to scale, businesses across material handling and manufacturing have been forced to explore new solutions.

More broadly, economic challenges like supply chain bottlenecks and labor shortages also exacerbate the need to change. We are currently seeing fluctuations in supply chain problems and lead times being extended from two months to four months. These types of economic problems force companies to search for solutions that allow them to become more resilient and resistant to these sorts of changes, now and in the future.

Unfortunately, managing these changes can be expensive. The automation of vehicles particularly requires high capital expenditures. When an organization is looking to buy a new vehicle, typically, they need to purchase not just one vehicle, but instead a fleet of multiple, similar ones. This large capital outlay results in it becoming a difficult and costly buy decision.

Robotics as a Service provides a new solution for businesses to tap into autonomy while avoiding the upfront investment required to shift their business. While the concept of renting vehicles for industrial use cases isn’t new, autonomous vehicles represent a novel option for businesses and their leaders.

What Are The Benefits of RaaS?

In the past, industrial vehicles have depended on the “Buy It and Use It” model. But as the “As a Service” model has grown and become a more widely available option, material handling organizations are beginning to see its many advantages.

One of the biggest advantages of the RaaS model is that vehicles are maintained by the service provider. We can look at self-driving vehicles as an example. For the end-user, autonomous vehicles are very simple to operate. You simply push a couple of buttons and the vehicle drives to the next station, effectively completing its desired tasks.

However, under the hood, the technology is very complex. Thus, offloading all of that maintenance to an outside organization makes the vehicles much easier to work with. The end-user gets to take advantage of advanced technology without having to staff up and train a maintenance crew. This further allows workers to shift their efforts to other, more productive tasks, making processes more efficient without disrupting workflows.

In addition, RaaS users can expand or contract their fleets, based on changing demand. For example, a business may choose to bring in more autonomous vehicles during the holidays to increase the speed by which goods can be processed. But, after this, they can then scale down their operations to meet their standard demand. This creates a more flexible, “just-in-time” solution where you’re matching throughput capability to what’s required, rather than overbuilding or playing catch up to your true demand. Specifically at Cyngn, we have designed our software platform in a way that allows the end-customer to see the business case in action and then scale the deployment later on.

The final advantage of the RaaS model is that by shifting from purchasing assets to a rental model, costs not only become more predictable but they can also be spread out. Instead of purchasing an autonomous vehicle outright, an organization can reduce its payments by extending them out over time.

What Are The Obstacles With RaaS?

As with any new, advanced technology, there are several obstacles to making this shift that make it more difficult for businesses to switch to RaaS. One roadblock to adoption is how an organization currently structures their capital. Many businesses budget for vehicles in a particular way but RaaS represents a shift from CapEx to Opex. Therefore, some companies have to consider how they’re changing their investment structure or how they lay out capital for their year in order to accommodate this new type of business model.

Talent and adoption is another roadblock to implementation. While new technology is a great way to retain and upskill talent, it requires additional training to enable workers to use the new technology.

Third, implementing this new technology can be undesirable for a customer that has been buying assets that have, for instance, a 10-year useful life-span. If an organization purchased a vehicle last year, it may not make sense for them to integrate a fleet of new vehicles before the shelf-life expires on the legacy fleet.

How Does Cyngn Ease Roadblocks to Adoption?

At Cyngn, we have built our products to be as simple and usable as possible. Yet, we recognize that it is still a new piece of technology that may have obstacles associated with implementation. It can result in a slight or big change in the way that organizations design their operations and can take time. Therefore, our job is to ensure that these changes are as minimized as possible in order to maximize the value that comes out of this technology.

A part of this is our ability to help businesses that have existing vehicles. Cyngn is able to support retrofits. It’s an “in-between” solution that means companies don’t have to retire their assets or overhaul their entire procurement department in order to (a) turn on autonomous and also (b) pay for it using RaaS. Rather than looking for a problem to solve, this approach allows us to lead with our solution and apply it to a variety of applications.

We are specifically seeing the most traction right now in very high-utilization applications. For instance, a fulfillment center where there is 16 to 24 hours of uptime. In this scenario, Cyngn could implement a simple, high-level service model where the organization utilizes a vehicle every single day for a year. This results in high-utilization and the company would be charged according to a monthly or annual type license.

As the “As a Service” model continues to rapidly grow and we see continuous innovations in the AV space, we expect to see many new options for how to use products as rentals. In turn, we will continue to see companies benefit from these service models, increasing the utilization of their assets, decreasing inefficiencies, and remaining focused on their core competencies. This shift will ultimately create different opportunities for us to change the way that we use products.

Podcast Episode Transcript:

Luke Renner: This is Advanced Autonomy. I'm Luke Renner. My guests today are Ben Landon and Jordan Stern. Ben is the VP of business development, and Jordan is the director of product management here at Cyngn.

Today we're going to discuss Robotics as a Service. Robotics as a Service represents a new paradigm, where key assets at your organization are rented, instead of owned. ABI Research predicts that there will be 1.3 million RaaS installations by 2026, generating over 34 billion in revenue.

For Cyngn, Robotics as a Service represents the easiest way for us to put autonomous vehicle technology into customers' hands without requiring our customers to staff up a maintenance team or a crew of engineers to get the most value out of such a cutting edge investment.

In this conversation, we'll discuss Robotics as a Service and dive into the ways the shifting paradigm will make it easier to tap into new technologies and get work done. Jordan, Ben, welcome to the show.

Jordan Stern: Thanks, Luke. Super happy to be here.

Ben Landen: Thanks, Luke.

Luke Renner: So, Ben, I'd like to start with you. What is Robotics as a Service?

Ben Landen: Fundamentally speaking, anything that's “as a service” means that you're shifting the model from an ownership, where you buy some asset outright from the get-go, into sort of a lease or rental type of model that involves a subscription.

So the primary difference is that when you own the asset, just as is the case when you buy a house, for example, you're responsible for everything that goes on with that asset. You need to handle maintenance, you determine how it's used on a day-to-day basis. The sale essentially typically ends your relationship with the seller. Whereas if you're renting again, if you're renting and your sink breaks, you contact your landlord and they take care of it, just as you would contact your service supplier for whatever “X as a service” product you're receiving. And they would offer you everything from maintenance to updates and upgrades, and it changes the dynamic of how you utilize the asset.

Luke Renner: And so, how are we seeing this across the industrial use cases lately?

Ben Landen: We are seeing a shift, especially when you think of some of the more expensive assets that are used in industrial settings, like vehicles, which is our focus here at Cyngn, is that those are high capital expenditures. When you need to buy a new vehicle, typically, it's also just not one vehicle. You typically need to buy a fleet of multiple similar vehicles. That is a very large capital outlay, and it's a difficult buying decision, and it's one that has its imperfections.

Just as we have been touted in autonomous consumer vehicles, we buy cars. They're typically the second most expensive asset we buy after our house, and on average, each of us utilize our vehicles at a 4% utility rate. If you do the math on that, you're getting a very poor bang for your buck, especially when you consider that all of these vehicles are depreciating assets.

Now, that's not dissimilar to what we see in industrial applications. The difference is that we're probably going to have higher utility rates than 4% in industrial settings unless you're buying an oddball machine that only does a very specific task that's used once in a blue moon within a workflow.

So the numbers are a little bit more in your favor, but you're also now we're talking B to B, we're talking enterprise operations. You're much more cognizant of your bottom line than a consumer who needs to buy a car to get to work.

Luke Renner: You know, I think this, “as a service” trend, people are most familiar with it in terms of software as a service, right?

This is the transition to the cloud that happened about 10 years ago. And as we track the “as a service” paradigm, moving from software over to hardware, this is a trend that's going to continue. So, Jordan, why is this shift happening?

Jordan Stern: A lot of the industries that we're talking about that could utilize robotics as a service, particularly when we're talking about indoor locations. If you think about the material handling industry or manufacturing or whatever it may be, a lot of those industries are undergoing massive amounts of change at the moment. And change can come from changing a business model, but it's also from increases in demand, they need to handle levels of scale that they didn't have before.

And when organizations and businesses in different markets undergo that type of change, the leadership at those companies looks for new solutions, looks for new ways to go and tackle those problems, and they analyze their business and say, how can we become more efficient? How can we move our investments around to make sure that we're investing in the things that really contribute to our bottom line? And robotics as a service is a new option for that. It's a new type of solution that maybe, they haven't thought about before. And rentals isn't something new per se for vehicle utilization in these spaces, that's been happening for a long time. But things like autonomous vehicles are new technology packages that sit on top of those that are new to these businesses and their leaders.

And so talking about robotics as a service is a new way to kind of think about how you use your vehicles, is an interesting new option for some of these organizations that are undergoing, kind of stress and change in the times that we're in today.

So I think a big reason why it's starting to pick up is because everyone's looking for a new option and a new way to handle what's happening in the world today. And even if we see fluctuations up and down, people are realizing that that's here to stay. Changes in these industries are here to stay. And so you need to become more resilient. And robotics as a service offers that type of solution. And it's a new, interesting way to implement new technology, which people are always looking to do.

Ben Landen: Yeah, I want to actually piggyback that with an example that I think merges some of those things together and makes them clear. Which is if you envision or think of a fulfillment center, for example, that operates year-round. But as you might expect, come the holiday season, they've got three extra volume to do because of all of the Christmas gifts and everything that are going around.

Now in the pre, as a service model, the paradigm would be either own a bunch of vehicles that you don't use when you're running one-third of the volume that you do for the holidays and then staff appropriately, too. So either have people on payroll that are part-time or waiting. And then you have to try to spool all those things up at the same time. It's expensive, or you're either carrying assets on your books and payroll that you're otherwise not utilizing well leading up to that.

Whereas if you have, and this is where the autonomy aspect of the as a service model comes into play. If you have vehicles that can do the work, you're already signed up to an "as a service" model. And the number of vehicles that you use is essentially just a byproduct of how much you want to scale up or scale down your contract for the period within which you're using those vehicles. You now have a much more flexible, kind of, more along the lines of just in time type of supply chain that you can run, where you're really matching your throughput capability to what's actually required, as opposed to needing to overbuild or play catch up to your true demand.

Luke Renner: Well, it seems like there are a lot of advantages then. I guess what I'm curious about is, why hasn't this been universally adopted yet? What are the obstacles to making this shift?

Jordan Stern: Actually I really enjoy talking about this question a lot, because when your technologies are implemented and things, everyone's always like to talk about what's going to be great about it and how it's going to help improve.

But one of the biggest ways that these types of technology is going to continue to work is making sure that people that want to implement it understand some of the difficulties that might occur when they do the implementation, or how they'll have to change their thinking with how they do their business.

And so when we think about roadblocks to adoption, there's a couple that come to mind for me. One of them is how they spend their capital currently. A lot of businesses are organized to think about the purchasing of vehicles and the utilization of those in certain categories. And now we're talking about a new business model for how they're paying for these types of services and a piece of technology that's sitting on top of it.

So some companies might have to think about how they're changing their investment structure or how they lay out capital for the year and their investments so that they can accommodate these new types of business models, something like Raas, robotics as a service, provides.

Another one to think about is talent and adoption. It's both a positive in this sense and sometimes can be a robot for adoption. So it's a great way to retain talent and upskill your talent. Getting them trained as robot operators and having them get to scale your new technology is fantastic, but that also takes a little bit of time.

Our products at Cyngn are built to be as simple and usable as possible, but it still is a new piece of technology that needs to be implemented. But it's also a slight change and sometimes a big change to how people design their operations and those changes can take some time sometimes. And our job at Cyngn and as a company is to make sure that those changes are minimized and it's as easy to implement as possible/ But anytime you implement a new piece of technology or business model like robotics as a service, you do need to think about how we're going to get people trained on this, how we're going to make sure we maximize the value that comes out of it. And so those pieces can be a bit of a roadblock to adoption as well.

Luke Renner: Ben, as you're talking to potential clients and potential customers of ours, how are you seeing those organizations are sort of talking through the change management aspect? Because it's not just a shift in how they procure equipment, it's also a shift in how they finance it, how they budget for it, and how they integrate it into their workflows.

Ben Landen: One of the advantages and what you often like to see when you're bringing innovative solutions to market is that you want to be innovative, but you want to stay within some familiarity window where you're not being so innovative that you're asking people to work with things that they've never seen before, anywhere under the sun.

So we do have the advantage that like you both mentioned already, SaaS models started being used going back a couple of decades now. So a lot of organizations, both on the selling the product offering as well as the buying side, have gone through some of the pain points of figuring out how accounting is different, how procurement is different. And large organizations, there's lots and lots of famous cases from 27 years ago, have gone through those pain points.

There are now established methods for best practices for SaaS accounting and buying. So we don't need to reinvent that wheel. It's more of a matter of when the organizations that we're working with are going to come around on procuring these types of products vehicle assets under that same type of paradigm. And there, it's just a matter of guidance and working together and seeing when that readiness occurs.

To me, one of the real, let's call it in one sense a roadblock to adoption, is the fact that it's hard to make an argument if a customer has been buying assets and they've been buying, some of these vehicles are 10-year useful life types of assets. If they bought one last year, it probably doesn't make sense for them to mothball that fleet of nine-year useful lifetime remaining assets, just for the sake of switching to a service model.

So on the one hand, that's a roadblock because it's one that I don't think is sensible for us to even try to overcome, it's not what the smart thing to do for an organization is. But our response to that and why we've focused as much as we have on existing vehicles, working with incumbents, and being able to support retrofits is, hey, let us ease you in with this in-between where you don't need to retire those assets, you don't need to overhaul your entire procurement Department and say we don't buy vehicles anymore, we only use them under a service model. We have this retrofit capability where you can have a hybrid model, you can own some assets, we can help you upgrade with our partner's assets that you already own.

And that can be a very natural stepping stone into oh wow, that small fleet that I've just retrofitted to being autonomous, within my much larger fleet, is doing wonders for me. I'd like to now talk to Cyngn about what vehicles I can license from the get-go without having bought the asset in doing the retrofit just to buy autonomous ready vehicles. Which is the very natural progression that we see of how we guide this and create value along the way and lower the barriers to entry and adoption.

Luke Renner: Something that I found interesting about the shift to robotics as a service is that there are almost as many revenue models as there are robots out there. Some organizations charge by time, you rent this thing for a certain number of months or years. Others charge by deliverables or even in the case of delivery robots, we have revenue models by distance traveled. What revenue model does Cyngn cover?

Ben Landen: This question goes hand in hand with how we generally view the products that we offer to our customers. Which is that we really think about what does the application need as opposed to, what can we build and then go push to applications that could use this.

So this goes hand in hand with how we've designed our system. The fact that we're vehicle agnostic. We're more software-focused. We change the sensor suite or change the vehicle based on what the customer needs are and the jobs that they need to do with that site.

And the financial model works in a similar way. Where we are seeing the most traction right now are in very high utilization types of applications. So we're typically talking anywhere from ideally 16 to even 24 hours of uptime. In some cases desired, in which case you can have a more simple high-level service model where you just say, hey, you want the vehicle for a year, it's going to be working every single day for that year. That utilization rate is so high that it makes sense to charge on a very high level like monthly or an annual type of license.

Now as we see more proliferation of these vehicles into various different types of applications, I think everything that you brought up could ultimately make sense and it needs to make sense for the customer in terms of we want our service model, our pricing model, to incentivize the customer to use the vehicle and to get value out of it.

Luke Renner: So zooming out of it. What impact do economic issues like supply chain bottlenecks and labor shortages have on the drive towards robotics as a service?

Jordan Stern: The bottom line is that this is the reason why people develop technologies to help with the changing world. And so as the supply chain woes that the world is seeing today continue to progress and hopefully get better in the future, but continue to be a thing. And in general, economic fluctuation, supply chain fluctuation is always going to be around.

And the way that this drives not only robotics as a service, but technology adoption is. What that technology adoption allows companies to do is be more resilient. You have to be able to be resistant to change.

And so as we see these fluctuations in supply chain problems and lead times being extended out to four months when they were two months, or seeing incredible increases in demand from one month to another one, it creates that drive for solutions like this particularly autonomous vehicle one. So the faster that those solutions can be deployed and we can get them in the hands of customers, the better chance they'll have at managing those fluctuations and being resilient to that change.

Luke Renner: Ben, anything to add?

Ben Landen: The workforce shortages are at the forefront of why “as a service” models make sense. And really, when you think of “as a service”, that's the buying model that goes hand in hand with, in my eyes, the more exciting piece, which is new and innovative technology that helps companies and helps people to operate more effectively and safely.

And that's really what we're focused on bringing and by nature of how that technology is offered, which is that these vehicles that we make autonomous are software-defined. It's the software that is decoupled from the hardware that we can push and update and maintain in. And as a service model, what that enables you to do is to mitigate the negative impact that you might feel from workforce issues.

So we touched on it before, but it's much easier to increase the size of your fleet once it's there and operating and train the folks who you do have working alongside the vehicles on how to do that safely, then to try to hire more people in the difficult hiring market that already exists. And hire people who have specialty talents, like operating a specific type of vehicle.

So we're directly helping to assuage the pain of, hey, I have jobs to do that are very specific, that require a certain type of skilled labor, and I can't find the people to do that because that's a widespread problem right now.

Luke Renner: So as we look ahead to the future, where do you see the “as a service” revenue model heading?

Ben Landen: We touched on this a little bit earlier, but I think we're just going to see lots and lots of new options of how to use products in an “as a service” model. And this goes back to why I actually, several years ago in my career, went from broadly working in the automotive space to being hyper-focused on autonomous vehicles, is that I'm very passionate about helping people to basically get more bang for their buck. And for me, that started with the desire to help to create a new generation of consumer vehicles that enable people to not own a vehicle if they don't want to, because right now we're sort of forced to. It's just how our commutes are structured.

I already touched on the 4% average utilization that the average person gets out of the car that they buy, the second most expensive asset. That just doesn't financially make sense. And I think that what we're going to see is enterprises starting to also benefit from those service models that let them increase the utilization of their assets, let them remain focused on their core competencies, not staff up a maintenance team for vehicles when you're a fulfillment company that wants to move packages around, not have to tweak nuts and bolts and fix tires that blow out.

So I think that we're just going to see a flurry of new options. And there's a lot of big shifts that are occurring that play into this going from blockchain technology and being able to essentially share assets in that regard because of the democratization of how you might be able to charge for those.

All of these shifts are going to create hyper granular and very different opportunities that might allow us to charge service models or to use assets or products on a per-instance basis or over a time basis.

And I think it's just really going to change the way that we use products, the way that we spend money. And I think in a way that generally is going to do away with a lot of the inefficiencies that we just have to take on when we're buying, especially expensive things outright, to own.

Raymond Wang, CEO of Greenland Technologies, joins the podcast and explores our partnership to bring autonomy to their industrial vehicle fleet.

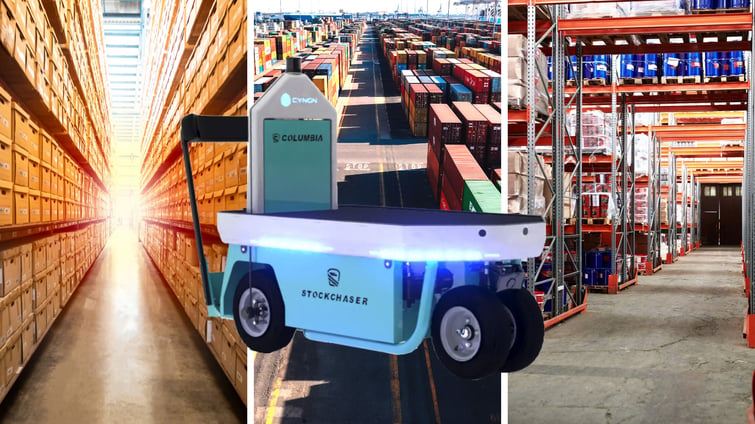

A seamless approach to turning your industrial vehicle fleet autonomous.

In this video, representatives from Columbia and GLF tell you a little bit more about the Cyngn partnership and the value these relationships are...